Iron removal

Groundwater often contains dissolved and undissolved iron and manganese. These elements cause brown deposits on the machine parts that come into contact with the water. As a result, installations suffer from poorly functioning processes, pollution and a shortened service life. Moreover, iron and manganese also give the water an unpleasant taste and smell.

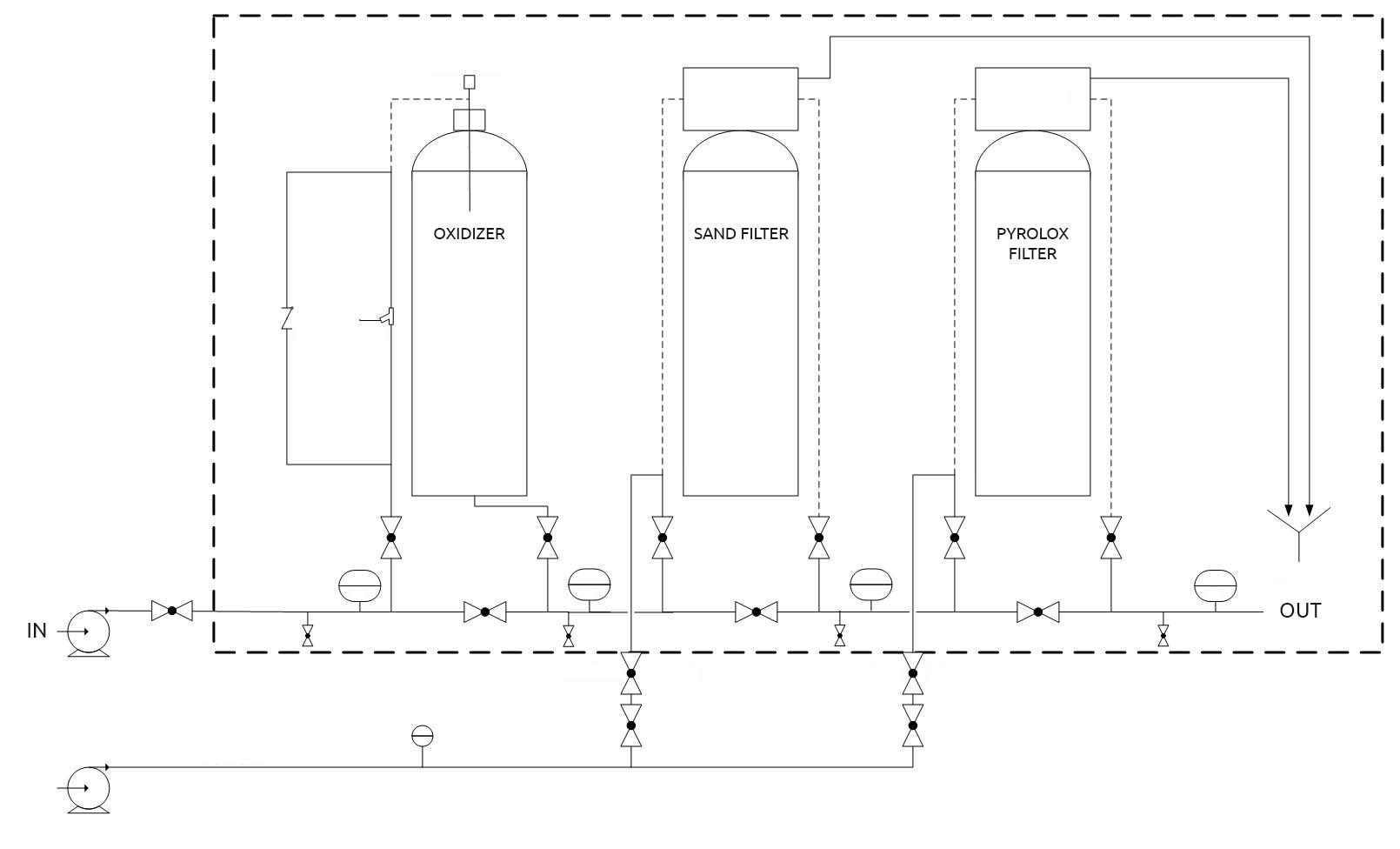

The best way to avoid all these problems is iron removal. The de-ironing process usually goes through an aeration phase and one or more filtration phases.

During the aeration phase, the water is aerated with dissolved iron (Fe²⁺) in order to oxidise the iron. The oxidation is usually carried out with compressed air. The oxidized iron (Fe³⁺) is no longer dissolved and will be separated as iron flakes in the sand filter. If necessary, a pyrolox filter removes the last iron residue after sand filtration.

The required phases in the process depend on several parameters, such as the application of the water, the oxygen level, the acidity, the CO₂ levels and the concentration of iron and manganese.

PCA can help you with this technology, both in design and construction of the installation.